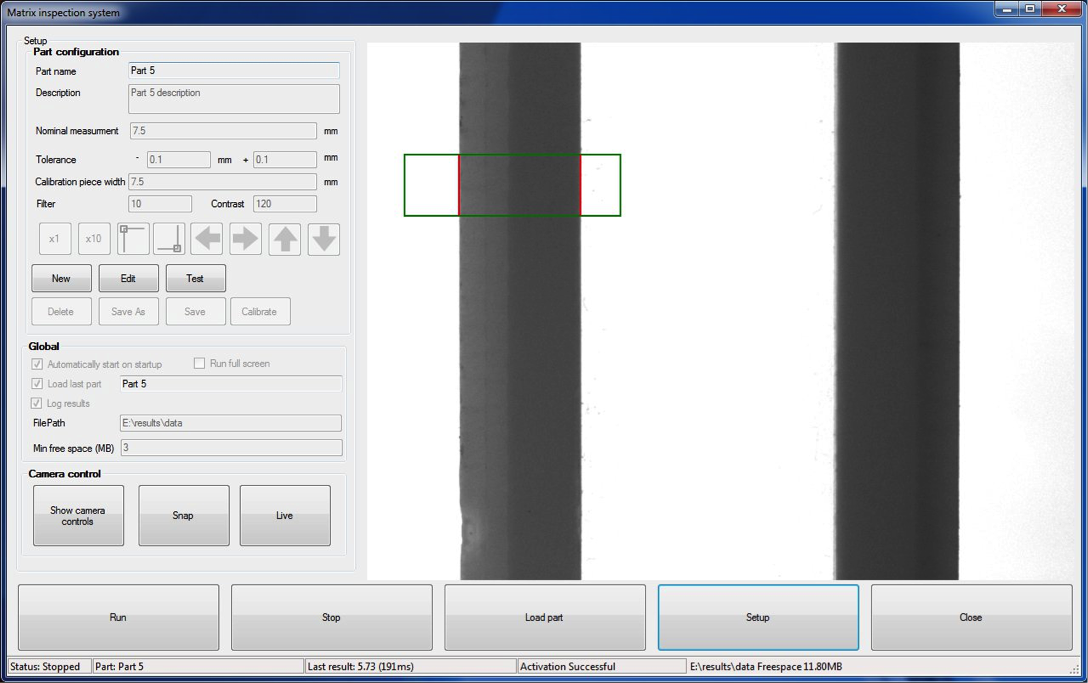

Vision systems

A typical vision system consists of several key components:

- A camera.

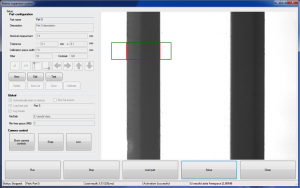

- Image processing software.

- Some I/O to control/feedback to the system.

- A user interface.

- A PC.

How much?

Each of these components is quite expensive, what could be done to lower the cost?

- The camera: Cameras used to be very expensive, on top of that, each camera would require an interface card inside the PC. Today there are a wide range of inexpensive USB cameras, no interface card and no PC slot required.

- Image processing software: Each installation would typically need a license. As my client writes and maintains their own image processing libraries they are in control of this.

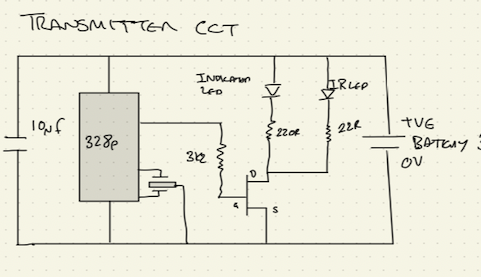

- I/O: Digital I/O not needed for this application (would normally be another expansion card in the PC).

- A user interface: Touch screen are normally used as they dispense with a keyboard and mouse. Normally quite expensive, could we use a tablet?

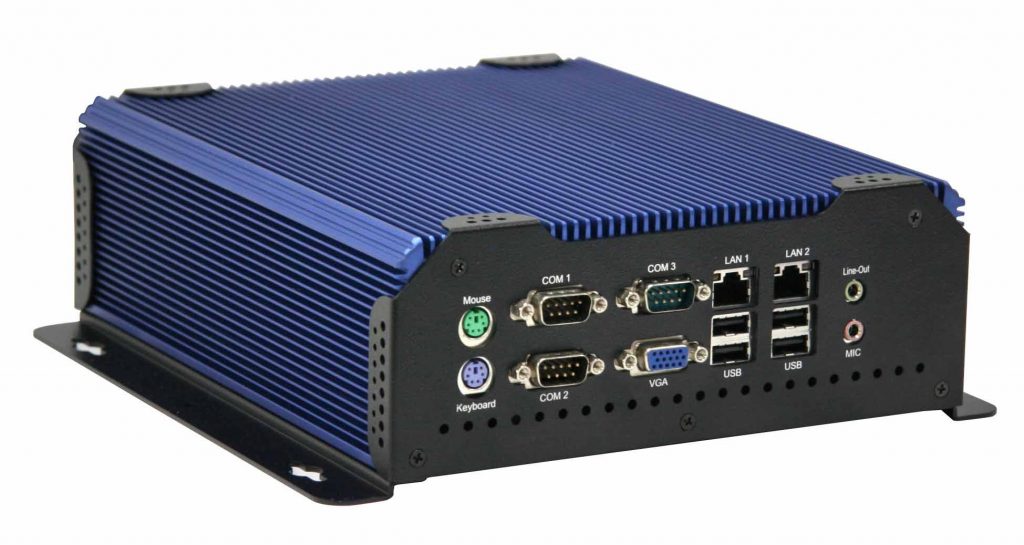

- The PC: A PC with expansion slots is normally required, we don’t need any so can get away with something much smaller, just a single USB port for the camera. Would a tablet be up to the task?

A tablet, really?

The image processing libraries are Windows PC based, porting this to iOS or Android would be a non-starter as it would take to long and have very limited, if any, camera support. I had a Toshiba 7″ tablet with one of the latest quad core Atom CPUs running windows 8.1, time for some experimentation.

A simple test application was created and loaded on to the tablet along with the camera drivers. This was run on the tablet and the times noted. The test were then run on several other platforms, core2, i3, i5 and i7 based systems. The results were quite surprising. I can’t remember the exact numbers but the tablet ran somewhere between a core2 and i3 system – excellent, this could work.

Power issues

Most tablets are charged through the USB port, we are using this for the camera so we used a splitter cable to connect both camera and charger to the tablet. Unfortunately this did not work, the camera functioned correctly but the tablet would not charge.

It turns out that many tablets can either charge OR use the USB, not both. The state of the USB data lines are read as the tablet it switched on and the mode selected. There are aftermarket options to get around this but they generally require a specific power up sequence (plug this in, switch that on, plug something else in), not good enough for industrial use.

After much searching a suitable tablet was found, a 10″ Lynx tablet running Windows 8.1. This had a USB port AND a separate charger connector – excellent!

Mechanics

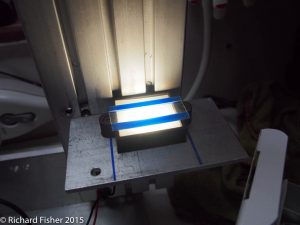

As well as the tablet and camera we needed to supply suitable lighting and mountings.

A stand was manufactured to hold the camera and lighting, this would bolt on to a bracket on the machine supplied by the end customer.

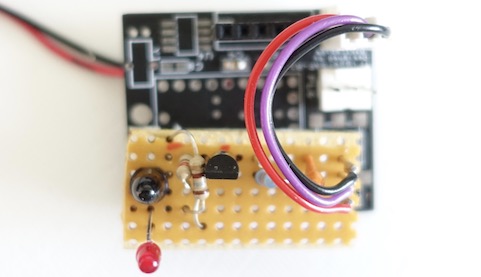

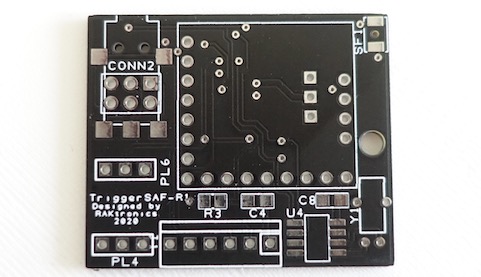

For the lighting a 10W 22mm LED was used. This needed an adjustable constant current source building, this was done and housed in a small diecast box.

The LED housing itself was manufactured using my 3D printer with some frosted acrylic across the to to defuse the lighting.

Onwards

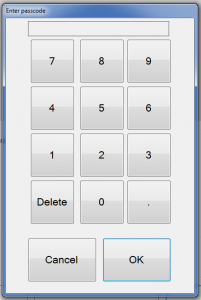

This was done and working, the next step was to hide the Windows OS from the user to prevent people ‘playing’ with the system. This proved to be more difficult than usual due to the way windows works on tablets, they are designed to run applications full screen but then use hardware buttons and gestures to get to the OS. Most of these were disabled so only someone with a knowledge of windows tablets would be able to gain access.

Performance

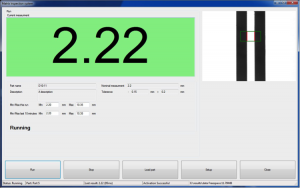

- Inspection speed: 5-10 measurements a second

- Max number of part types: unlimited, up to storage space.

- Result storage: up to size of disk, local or network.

- Software: VB.net.

- Image processing: Customers own libraries.

Epilogue...

The system worked great, for a time, but during a long run the tablet battery would go flat as it could not run the tests, power the camera and charge the battery at the same time. The machine was powered off when not it use and the battery would discharge during this time. On the subsequent start up would take a little while to charge sufficiently to be able to start the tablet, not great!

The only answer in the end was to fit a small PC and monitor, a difficult task given the limited space on the system.